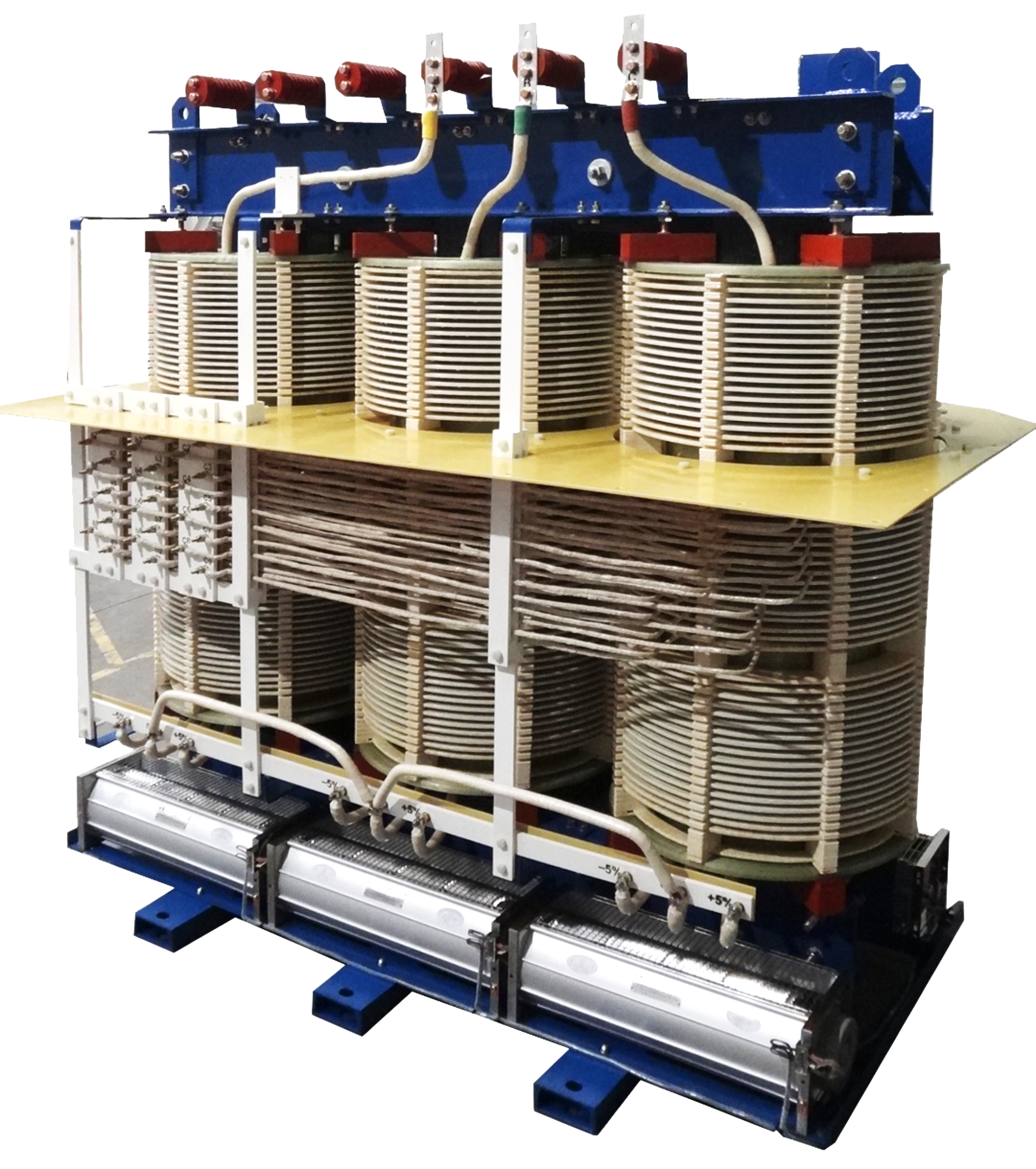

Dry Type Transformers

Medium voltage cast resin and VPI transformer solutions

Environmentally friendly alternative to liquid-filled transformers

As one of the largest manufacturers of cast resin transformers in the world, we design, test and build transformers to meet some of the most challenging applications, sizes and configurations in the market today. Our engineers have been leading the industry for over 35 years in technological advancements, quality and customer support.

Over the years, we have evolved to offer a variety of dry-type transformer solutions including our medium voltage cast resin dry type transformers, vacuum pressure impregnated (VPI) transformers and various application specific solutions.

Maintaining reliable power is a necessity for data centers, renewable energy sites, commercial and industrial buildings and utility substations. We can provide a complete solution specified to your needs. Our efficient production and delivery processes mean you’ll get your equipment faster, helping you meet tight deadlines.

Industry-Leading Lead Times

2 - 3 Weeks RFQ Lead Times

2 - 4 Weeks Drawing Approval

22 - 24 Weeks Cast Resin Transformers

20 - 22 Weeks VPI Transformers

Cast Resin Transformers

Cast resin (epoxy) transformers are the highest on the evolutionary scale of transformer design and offer the best combination of electrical and mechanical performance factors. The robust structure achieved by casting the windings in a solid shell of epoxy provides mechanical strength unsurpassed by any other transformer available on the market. Cast resin transformers offer safety, environmental and sustainability goals set forth by many industries.

Additional Features and Benefits

- Low to no maintenance

- Self-extinguishing insulation system

- Can be used in a variety of environments

- Can be used up to voltage levels in the 35 kV class, basic impulse levels (BIL) to 200 kV and partial discharge levels to 10 pico-coulombs and below

- Overload capable and fan options for extra cooling

- Lower installation costs than oil-filled transformers

Current Size Range and Rating Capability

| Voltage | Up to 40.5 kV |

| Basic Impulse Level (BIL) | 200 kV (without surge suppression) |

| Rated Power | 100 kVA – 45 MVA |

| Primary Voltage | 480 V – 40 kV |

| Typical Primary Voltages (kV) | 2.3, 4.16, 8.7, 12.47,13.2, 13.8, 25, 34.5 |

| Secondary Voltage | 0.208, 0.24, 0.48, 2.4, 4.16, 6.9, 12.47, 13.2, 13.8 |

Cast Resin Solution Advantages

Environmentally friendly alternative to liquid-filled transformers

Compact design for additional space-savings

Superior dielectric properties

Robust structure protects against damage due to electrical faults and heavy surges

VPI Transformers

VPI transformers are an excellent alternative in applications which call for an environmentally friendly, economical solution. They reduce flammability concerns, require less maintenance, and are less prone to contaminating the surrounding environment than oil-filled transformers—avoiding the need for oil containment during construction.

Product Standards

- IEC 60076-1-5

- IEC 61378-1:1997

- IEEE C57.12.01-2020

VPI Solution Advantages

Environmentally friendly alternative to liquid-filled transformers

Designed with self-extinguishing properties for enhanced safety

NOMEX insulation promotes uniform cooling—reducing dielectric loss

Current Size Range and Rating Capabilities

| Voltage | Up to 35 kV |

| Basic Impulse Level (BIL) | 110 kV |

| Rated Power | 100 kVA – 14.5 MVA |

| Primary Voltage | 600 V – 15 kV |

| Typical Primary Voltages (kV) | 2.3 kV, 4.16 kV, 8.7 kV, 12.47 kV,13.2 kV, 13.8 kV, 15 kV |

| Secondary Voltage | 208V, 240V, 480V, 2400V, 4160V |

Additional Transformer Options

- Reactors

- Submersible network transformers

- Up to 54 pulse transformers

- Water cooled reactor

- Phase shifting

- Zig zag / grounding transformers

- Low voltage PDU transformers

- EV charger application specific

- Medium voltage transformer & switch combo

Enclosure Options

Choose from a variety of enclosure options to meet your specific system needs. Our enclosures are designed to meet all CSA and UL 50 requirements.

| Type | Description |

| NEMA 1 | Designed primarily for indoor use. This general-purpose enclosure is primarily designed to minimize the risk to personnel of contact with live or hazardous parts. The enclosure also protects against falling dust and debris. |

| NEMA 12 | Designed primarily for indoor use. This general-purpose enclosure is similar to NEMA 1 but also provides some additional protection against dripping noncorrosive liquids. Meets drip, dust and rust resistance tests. |

| NEMA 3R | Designed for indoor and outdoor applications. The enclosure provides protection against falling dirt and windblown dust, weather hazards such as rain, sleet and snow, and is undamaged by the formation of ice. |

| NEMA 4/4X | Designed for indoor and outdoor applications. This watertight design meets the NEMA requirements for excluding at least 65 GPM of water from a one-inch nozzle delivered from a distance of not less than 10 feet for five minutes. Used outdoors on ship docks, in dairies, and in wastewater treatment plants and breweries. X (as in 4X) indicates additional corrosion resistance. Note: NEMA 4/4X does not indicate submersible. |

| AFWF Marine Rated | Designed for shipboard, platform and marine applications. This Marine Water Cooled/Hydro Cooler design enhances protection for your transformer in the harshest environments. |

Quality Certifications

JST Power Equipment fully meets ISO9001, ISO14001,and OHSAS18001 certifications and standards. Our products meet GB, IEC, IEEE, NEMA, CSA, JEC and other international and domestic electrical engineering standards including UL, CE, and EU.

Contact Us Today

Have a question for our team? Get in contact with us today.